Ролики заднего переключателя CeramicSpeed Oversized for Campagnolo 12s EPS Alloy 607 stainless steel g

Manufacturer bike frame size: CeramicSpeed

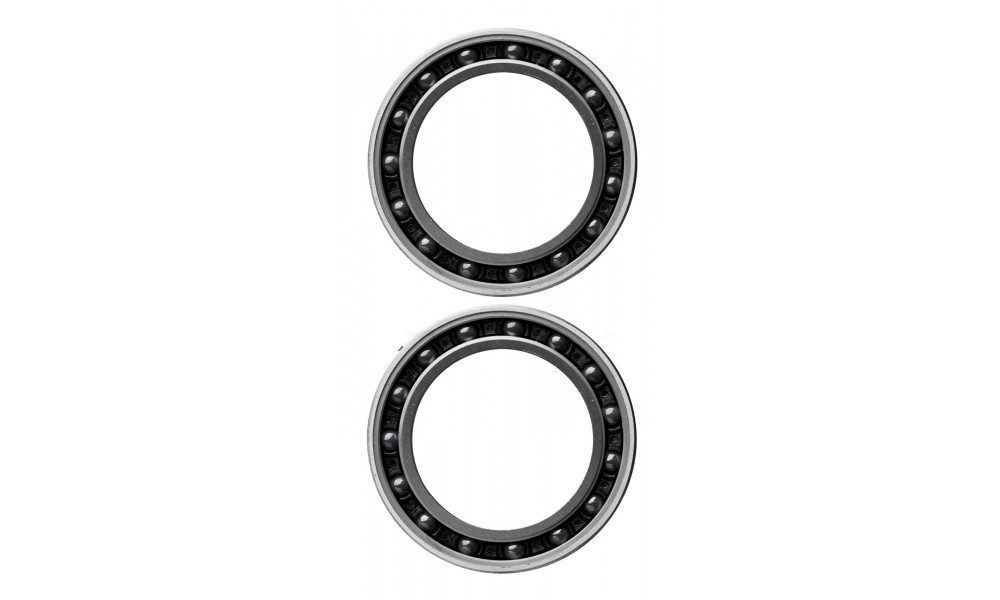

The CeramicSpeed bearing set for Campagnolo Ultra-Torque is compatible with original Campagnolo Ultra-Torque press fit bottom bracket cups. It's an 86 mm wide, 41 mm inner diameter shell. With the Campagnolo Ultra-Torque Pree Fit Cups, you're pressing the bearings onto the Campagnolo Ultra-Torque spindle, then fitting the cranks into the bottom bracket.

CeramicSpeed COATED Ceramic Bearings - ultimate performance, resistant to corrosion, very low friction, high durability, lifetime warranty

IN THE BOX:

RELATED TECHNICAL INFORMATION:

LIFETIME WARRANTY OF CERAMICSPEED COATED BEARINGS - All CeramicSpeedCOATEDproducts are covered by a lifetime* warranty! *PLEASE READ WARRANTY TERMS and CONDITIONS here: https://www.ceramicspeed.com/en/cycling/support/warranty-program/lifetime-warranty-terms-and-conditions

CERAMICSPEED COATED CERAMIC BEARINGS - Like all CeramicSpeed Bearings, our coated products are handbuilt in Denmark. Building a coated bearing adds a number of extra steps to the process. The CeramicSpeed balls and steel races are matched to the micron after which, each set of races is coated. The races are kept together in pairs through the entire process and after coating, each set needs to pass the quality control before they go into production. CeramicSpeed’s coated products offer the ultimate gains in performance and longevity. The unique coating features several attributes that improve the longevity of CeramicSpeed Bearings. The increased hardness of the races, combined with the smoothness of the CeramicSpeed Balls results in virtually no wear on the bearing. The unique coating is a metallic layer that covers the bearing races and makes them 75% harder than steel. Thanks to this, they are highly resistant to corrosion and the coating provides an even lower friction than our standard bearings. Even if the bearing is contaminated with degreaser, water or mud, the risk of bearing failure due to corrosion is negligible if you choose the coated version.Longetivity comparison diagram: see HERE

Within comprehensive research and development program, the special coating has been developed in cooperation with a European coating specialist. Applied to the bearing’s steel races, through an advanced process that ensures an even, smooth and homogeneous surface, the coating formula improves even further the high quality of CeramicSpeed Bearings.Thanks to the coating’s high resistance to corrosion – even if the bearing is contaminated with degreaser, water or mud, the risk of bearing failure due to corrosion is negligible. We recommend choosing CeramicSpeed Coated Bearings for unmatched longevity and incredibly low friction.Friction comparison diagram (lower is better): see HERE

ALL ROUND GREASE - Designed to suit the maintenance of CeramicSpeed Bearings, the CeramicSpeed All-Round Grease maximizes your bearings’ lifetime and performance. This type of grease is a low to medium viscosity lubricant and works as the best compromise between friction influence and lifetime. We recommend it for optimal use in dry and sunny weather conditions, where no or very little contamination threatens the bearing. The application covers mostly road riding conditions, however it can be used off-road in the same weather settings, on all types of CeramicSpeed Bearings. When lubricating your bearings, we recommend a fill rate of 60-80%.

MAINTENANCE OF CERAMICSPEED COATED BEARINGS - Coated Bearings are more resistant to lack of lubrication when it comes to wear and damage on the bearing. Nonetheless, this does not mean that the need for maintenance is completely eliminated.Depending on the riding conditions it is recommended once a year to re-grease your CeramicSpeed Bearings to achieve the best performance in terms of low friction and longevity.If used in very wet or muddy conditions, maintenance might be required more often.If high pressure washer is used, please do not point jet stream to any of bearings (headset, bottom bracket, wheel hub, full suspension links) as it may wash out the grease.

Картридж каретки CeramicSpeed PressFit Cups Coated for Campagnolo UltraTorque 25mm (101344)

Ролики заднего переключателя CeramicSpeed Oversized for Campagnolo 12s EPS Alloy 607 stainless steel g

Картридж каретки CeramicSpeed Gravel Coated BBright / PF46X79 for Shimano/FSA/Rotor 24mm black (110958)

This store asks you to accept cookies for performance, social media and advertising purposes. Social media and advertising cookies of third parties are used to offer you social media functionalities and personalized ads. Do you accept these cookies and the processing of personal data involved?

| Имя файла cookie | Поставщик | Назначение | Истекает |

|---|---|---|---|

| cookiesplus | bikko.lt | Stores your cookie preferences. | 1 year |

| PrestaShop-# | bikko.lt | This cookie helps keep user sessions open while they are visiting a website, and help them make orders and many more operations such as: cookie add date, selected language, used currency, last product category visited, last seen products, client identification, name, first name, encrypted password, email linked to the account, shopping cart identification. | 480 hours |

| show-coutry-select |

| Имя файла cookie | Поставщик | Назначение | Истекает |

|---|---|---|---|

| collect | It is used to send data to Google Analytics about the visitor's device and its behavior. Track the visitor across devices and marketing channels. | Session | |

| r/collect | It is used to send data to Google Analytics about the visitor's device and its behavior. Track the visitor across devices and marketing channels. | Session | |

| _dc_gtm_UA-* | Google Analytics | ||

| _ga | Registers a unique ID that is used to generate statistical data on how the visitor uses the website. | 2 years | |

| _gat | Used by Google Analytics to throttle request rate | 1 day | |

| _ga_# | Used by Google Analytics to collect data on the number of times a user has visited the website as well as dates for the first and most recent visit. | 2 years | |

| _gd# | This is a Google Analytics Session cookie used to generate statistical data on how you use the website which is removed when you quit your browser. | Session | |

| _gid | Registers a unique ID that is used to generate statistical data on how the visitor uses the website. | 1 day |

| Имя файла cookie | Поставщик | Назначение | Истекает |

|---|---|---|---|

| _gcl_au | Google Adsense |